Thermal spraying is a technology which improves or restores the surface of a solid material. The process can be used to apply coatings to a wide range of materials and components, to provide resistance to: Wear, erosion, cavitation, corrosion, abrasion or heat. Thermal spraying is also used to provide electrical conductivity or insulation, lubricity, high or low friction, sacrificial wear, chemical resistance and many other desirable surface properties.

Thermal spraying is widely adopted across many industries as a preferred method. It has huge scope to extend the life of new components or through the use of tried and tested techniques, to repair and re-engineer worn or damaged components.

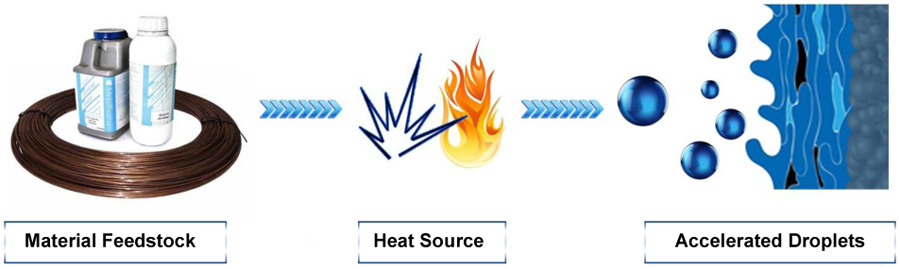

All methods of thermal spraying involve the projection of small softened particles onto a cleaned and prepared surface where they adhere to form a continuous coating. Combined thermal and kinetic energy causes the particles to flatten or ’splat’ onto the surface, and onto each other, to produce a cohesive coating of successive layers.

Metallisation Ltd is the only UK manufacturer and worldwide supplier of metal spray equipment, consumables, wires and powders. The company is proud to be considered as leading experts worldwide in the supply and support of advanced, innovative surface coating technology.

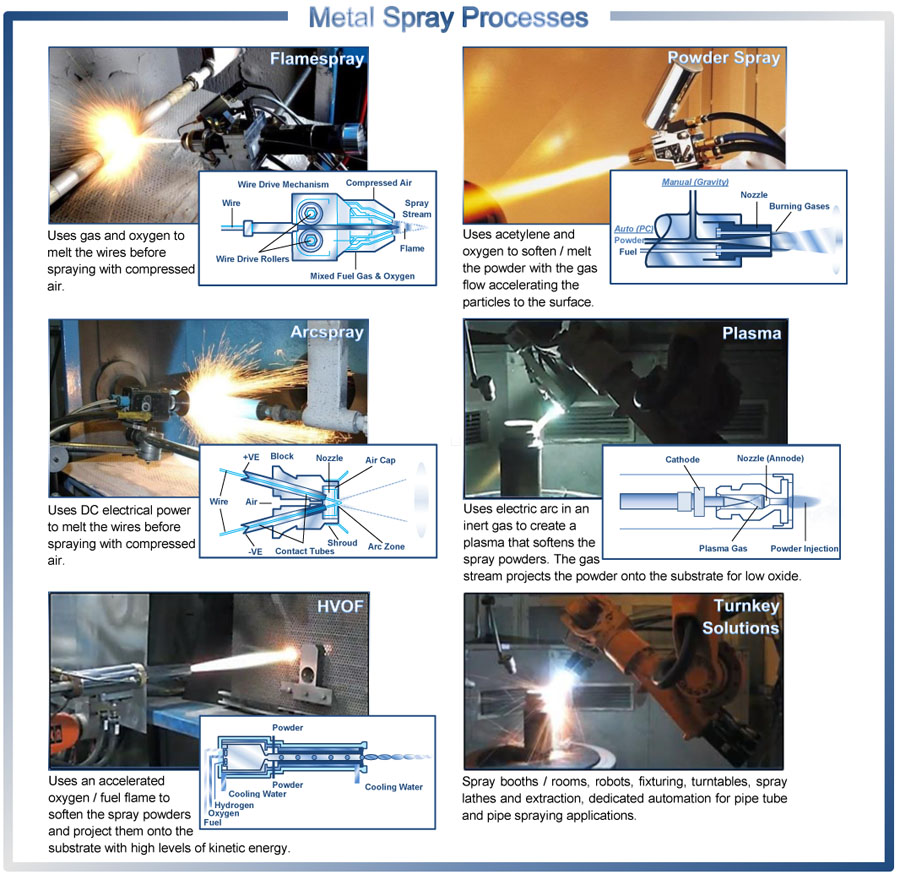

All five thermal spray processes can be used to apply ‘engineering coatings’ to modify the surface properties of an item. Engineering coatings can provide such properties as enhanced wear resistance, thermal barriers, electrical / thermal conductivity, hard-chrome replacement and insulation across a wide range of applications.

Metallisation Flamespray and Arcspray equipment is also used to apply ‘corrosion protection’ coatings of zinc, aluminium and zinc / aluminium alloys onto steelwork such as bridges, gantries, ships, off-shore platforms, gates / fences and vehicles. Commonly used as an alternative to galvanising.

Typical applications and materials

Typical applications and materialsA huge range of components benefit from thermal spraying, either as part of the original manufacturing process or as a reclamation or re-engineering technique. Some materials are used for small niche applications and other materials are sprayed by the tonne. Each application uses a combination of process and material to yield the desired benefits.

Reclamation and re-engineering of a wide range of rotating and moving parts from machines of all kinds, including: Road and rail vehicles, ships, aircraft, pumps, valves, printing presses, electric motors, paper making machines, chemical plant, food machinery, mining and quarrying machinery, earthmovers, machine tools, power generation and aerospace turbine repair, landing gear (chrome replacement) and virtually any equipment which is subject to wear, erosion or corrosion. This is done using either arc spray, flame spray or HVOF systems to spray steels, nickel alloys, carbides, stainless alloys, bronzes, copper and many other materials.

New components which benefit from the enhanced surface properties that thermal spraying provides, include: Gate and ball valves, rock drilling bits, and down hole tools for the oil and gas and petrochemicals industry, hydraulic piston rods, print rollers, fluid seals, aerospace combustion chambers, turbine blades. Thermal sprayed coatings are used on a vast range of components which operate in adverse environments where, erosion, wear, corrosion or heat, conspire to reduce component life. Component life is significantly prolonged by using arc, flame, plasma, or

New components which benefit from the enhanced surface properties that thermal spraying provides, include: Gate and ball valves, rock drilling bits, and down hole tools for the oil and gas and petrochemicals industry, hydraulic piston rods, print rollers, fluid seals, aerospace combustion chambers, turbine blades. Thermal sprayed coatings are used on a vast range of components which operate in adverse environments where, erosion, wear, corrosion or heat, conspire to reduce component life. Component life is significantly prolonged by using arc, flame, plasma, or  HVOF systems to apply metals, ceramics and carbides.

HVOF systems to apply metals, ceramics and carbides.